Himalayan nettle fiber

Himalayan nettles are shade tolerant, growing under the forest canopy and thus coexisting with forests. They are distributed at elevations between 1,500 and 3,000 m that are not suitable as farmland.

A hat knitted with a blended yarn of Himalayan nettle cotton, and banana leaf-derived fibers (has a wool-like texture despite not using animal fibers)

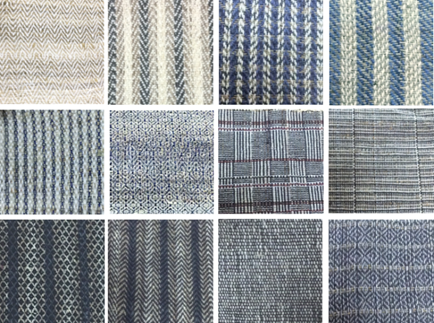

Woven fabrics with diverse textures made from the Himalayan nettle fiber. Being strong, they can be used for products like sofas and cushions.

Source plants

- scientific name

- Girardinia diversifolia (Limk) Fris

- general name

- Himalayan nettle, Allo

- overview

-

Himalayan nettles are an herbaceous perennial that belongs to Urticaceae and multiply via seeds and roots. They are distributed in tropical Africa, India, Nepal, Sri Lanka, Myanmar, Thailand, Malaysia, Indonesia, Southern China, and Taiwan. They are cultivated to obtain fiber in Southern India but are not a popular cultivated plant in other regions. Himalayan nettles are shade tolerant and, in Nepal, grow naturally on the forest floor and in valleys of the Himalayas (elevations 1,500–3,000 m) that are not suitable as farmland.

Product characteristics

- use

- The fiber, made from the stem bark of Himalayan nettles, is used to make goods like carpets, fabrics, bags, and clothing. Also, the roots and leaves are used as traditional medicine and are said to be effective for skin diseases (e.g., atopy), headache, arthritis, stomachache, and fever, as well as having insect deterrent and antibacterial effects.

- area

- Nepal and India

- overview

-

The fiber made from the stem bark of Himalayan nettles is strong, smooth, and light. It has long been used by the people in the mountainous regions of the Himalayas. Himalayan nettles also have effects that make them useful in traditional medicine; the local people believe that clothes made from the fiber, when worn, are beneficial for skin and other diseases. In Nepal, carpets that use blended yarn made from Himalayan nettle fiber have been produced since around 2005. Currently, approximately 95% of the annual production of the yarn (200–300 t) is used to make carpets for export. Carpets made from Himalayan nettles are thick and use approximately 5.35 kg/m2; they are traded at approximately 15,000 yen/m2, making them an important export for Nepal, with the estimated market size of over 500 million yen. Himalayan nettle fiber requires manual spinning, as its fiber length is 1.5 m (longer than other natural fibers) and would become entangled in a spinning machine. Therefore, it is believed that for the poor people who live in the mountainous regions of the Himalayas, doing it all — harvesting Himalayan nettles, making yarn from the fiber, and selling the yarn to carpet factories —is providing them with a valuable income source. On the other hand, if purchase prices that are worth the days and effort put into yarn making are not set, it would be difficult to maintain incentives for the local people to continue making it. Thus, it may be difficult to secure sustainable and stable supply of the yarn. The yarn made from Himalayan nettle fiber can also be used to make bags and clothing, as it can be dyed and woven.

Plant fiber with the texture like animal fiber (e.g., wool)

Widely known natural fibers of plant origin are jute and hemp, but these fibers are coarse and relatively hard. On the other hand, Himalayan nettle fiber has wool-like softness, and yet it lacks an oily smell, which is characteristic of animal fibers; therefore, Himalayan nettle fiber has properties that can appeal to consumers who would rather avoid animal fibers. Also, Himalayan nettle fiber is a raw material for multifunctional fabrics, its hollow structure gives it a warming effect in winter and cooling effect in summer; it also has antibacterial and fire-retardant properties. Therefore, while the fiber is currently used mainly to make carpets, it has potential for other commercial applications. However, as mentioned, manual spinning is necessary due to the fiber’s physical characteristics, which make the use of spinning machines difficult. Its low production efficiency means sales prices tend to be higher, compared to other fiber-derived products.

Export and import trends, demands in Japan

A large proportion of Himalayan nettle fiber carpets produced in Nepal is exported to the U.S., Germany, Canada, and Italy, among other countries. The figure below shows changes in the export value of Himalayan nettle fiber carpets. The carpets appear to be exported to Japan, too; however, the average annual export value for the period 2010–2016 was very small, approximately 2.5 million yen.

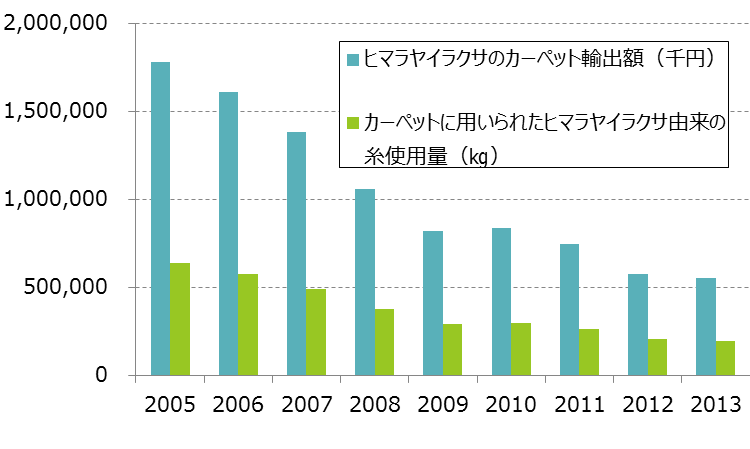

Changes in the export value of Himalayan nettle fiber carpets and the amount of the yarn used

Recently, the export value of Himalayan nettle fiber carpets has been on the decline; the primary reason being a drop in the popularity of thick and heavy carpets. Also, other than carpets, Himalayan nettles are processed into handicrafts (e.g., bags, fabrics, and clothing) for export, with an export value of approximately 2 million yen, which is very small compared with the export value of the carpets. For the poor people in the mountainous regions of the Himalayas, industries associated with Himalayan nettles, which coexist with forests, are a valuable source of income and if that income increases, incentives for forest conservation may also increase. In view of this, development of new products that use Himalayan nettle fiber is expected.

Market prospects

As mentioned, Himalayan nettle fiber requires manual spinning as it cannot be fed into spinning machines; therefore, the sales prices of products that use the fiber as a raw material tend to be high. The BFPRO commissioned the Institute for Himalayan Conservation to investigate the business potential of Himalayan nettle fiber. As part of the study, the possibility of using machine spinning for the fiber, by blending it with other fibers, was investigated. Among the several samples tested, the one with a mix of Himalayan nettle (40%), cotton (40%), and banana leaf-derived fibers (20%) was able to be subjected to machine spinning. The resultant blended yarn had a simple and natural texture, with a smooth gloss from the banana leaves and an unbleached color. Hats were knitted using this yarn (see a photo above) and were presented to a maker of Asian clothes and miscellaneous goods, who subsequently ordered 6,000 hats. The company, when asked their impression of the fiber (yarn) blended with Himalayan nettle fiber (yarn), said: “We have been importing yarns from China. This blended yarn is warm, soft, and smooth so we believe it has a potential for developing products for Spring and Fall – intermediate products between wool, suitable for winter, and cotton, suitable for summer. If the use of the yarn contributes to forest conservation, it’s even better – we want to use it. We will name the yarn “Himalaya” and want to introduce it to the production lines of our standard items.” It was suggested that, by supplying the prototype yarn to businesses and asking their impression of it, transactions may occur despite its relatively high price, once businesses and consumers recognize the functions and benefits of Himalayan nettle fiber, which other fibers do not have. Also, commercial values of clothes and miscellaneous items are influenced by their designs, as well as their quality. In Nepal, there are traditional fabrics with dyes and designs that vary from region to region and from tribe to tribe (see a photo above). The commercial value of Himalayan nettle fabric will increase by incorporating designs that suit the tastes of consumers in developed countries, while making the best of the characteristics of these traditional fabrics. Also, one way to increase its merchantability is to sell a story: by purchasing products made from Himalayan nettles, consumers can contribute to the improvement of the livelihood of poor people in the Himalaya’s mountainous regions and the conservation of forests in which the plants grow. Already, some European companies that deal with fair-trade products are selling products that use the fabric, such as bags, with a story that the purchase of such products helps improve the livelihood of the local people. For this strategy to work, it is essential that not only the local people in Nepal but also NGOs and businesses in developed countries be involved.

- references

-

- M.Brink and R.P.Escobin (Eds.) 2003: Plant Resources Of South East Asia, 17 Fibre Plants, Backhuys Publishers, Leiden, The Netherlands

- Micro Enterprise Development Programme (MEDEP) 2010: Value Chain Based Approach to Micro-Enterprise Development, Value Chain Analysis-Allo