- Knowledge Overview

-

Forestry is an industry that obtains lumber by growing trees in forests. When timber is obtained from trees, parts such as bark and branches are left over, and these leftover parts are called forestry residues. Generally, wood is extracted from trees in factories outside a forest. Therefore, forestry residues accumulate as waste in lumber factories. Compost made from such forestry residues is called bark compost (Figure 1). The word “bark” in the name refers to the tree skin. This is because general forestry residues contain bark. In Japan, bark compost began to be made from forestry residues around 1955, and factory production of bark compost started around 1965. The use of bark compost in Japan has expanded mainly for vegetable cultivation. A project is underway to use bark compost as seedling material for afforestation and return it to forests. In this way, bark compost is expected to play a part in sustainable forest management by utilizing forestry residues.

Figure 1. Bark compost - Background (history and development)

-

The production of bark compost began in the United States around 1950. Since then, composting technology has advanced by inoculating the wood-decaying fungi of the genus Atractylodes. Following the start of using bark compost in the United States, research on the development and practical application of compost using forestry and agricultural residues began in Japan in the late 1950s. Resulting data showed that mixing traditionally used rice bran and chicken manure with forestry residues promoted compost fermentation more rapidly in Japan than using the same method employed in the United States. When bark compost research first began in Japan, the composting of forestry residues was promoted as a method of disposing of forestry residues discarded at lumber factories. However, research has since recognized their effectiveness as compost.

In the 1960s, under the guidance of the National Forestry Experiment Station, factories that had previously disposed of forestry residues as waste began to manufacture and sell bark compost. As the number of businesses involved in bark compost increased, the Japan Bark Compost Association was founded in 1967, followed by the establishment of the National Bark Compost Industry Association in 1976. In the same year, unified quality standards were established by both associations, expanding the market distribution of bark compost.

- How to Apply Knowledge

-

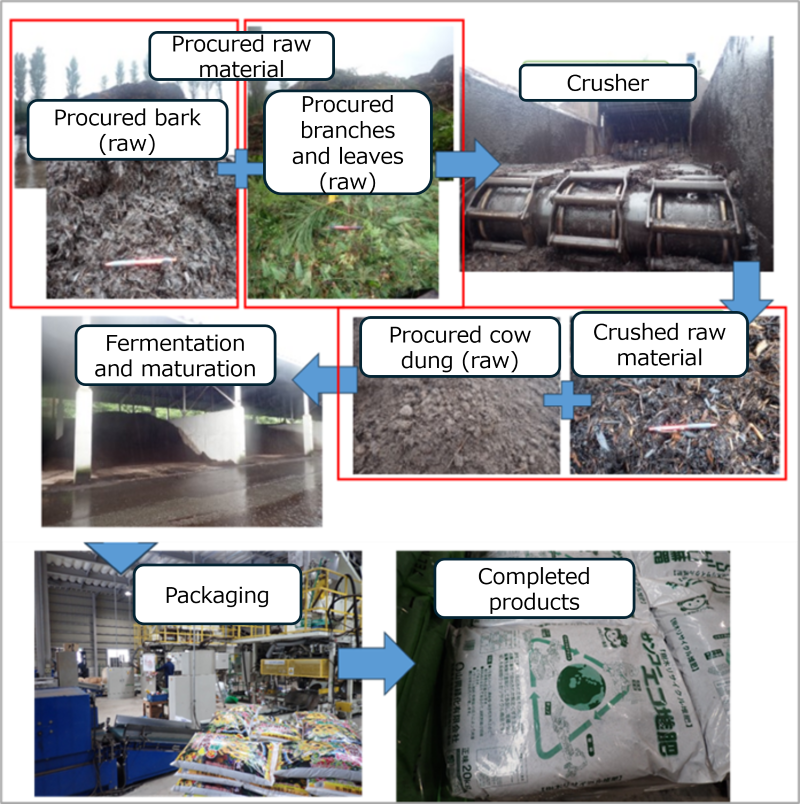

Currently, bark compost produced in Japan is made primarily from bark that is generated in large quantities during wood chip production and lumber sawing, with forestry residues such as branches, leaves, and roots used as secondary ingredients and with livestock manure such as cow dung and food waste added as fermentation accelerators, before being fermented.

The general bark compost manufacturing process is divided as shown in Figure 2. After being procured as a raw material, forestry residues are crushed, a fermentation promoter is added, and the compost is matured while being turned over as necessary to complete the composting process. The timing of this maturation and turning-over is determined by checking the moisture content and temperature changes.

Figure 2. Typical bark compost manufacturing process - Composting Manual

-

*This manual was created by the International Green Promotion Center, which was commissioned to the Japan Forest Technology Association as part of the FY2023 Forest Knowledge Utilization Promotion Project in Developing Countries. The original is in Vietnamese, and the English version is a provisional translation.

- Examples of Applying Knowledge

-

In Japan, bark compost is widely used as an agricultural fertilizer and soil conditioner, horticultural potting soil, flower beds and greening for landscaping, spray-on base material for greening slopes and rock faces (Figure 3), etc. In recent years, research has been advancing on the practical use and application of bark compost as a basic soil material for container seedlings (Figure 4) used in reforestation.

Figure 3. Greening of slopes and rock faces

Figure 4. Container seedlings - Positioning and Characteristics of Knowledge in Japan

-

Bark compost is classified as a special fertilizer under the Fertilizer Control Act. It is also designated as a soil improvement material, by government ordinance under the Soil Fertility Improvement Act. Producers are members of the National Bark Compost Industry Association and the Japan Bark Compost Association, distributing products that comply with quality standards.

- Owners/inheritors of knowledge

-

- General Incorporated Association, Japan Forest Technology Association

- National Bark Compost Industry Association

- Related URLs (in Japanese)

-

- Japan Bark Compost Association (NPO) https://www.bark-compost.com/ (accessed 2023/10/4)

- National Bark Compost Industry Association http://zmchip.com/ (accessed: 2023/10/4)

- Sanko Greenery Co., Ltd. https://sanko-ryokka.com/ (accessed: 2023/10/4)

- What is bark compost? https://ecologia.100nen-kankyo.jp/column/single261.html (accessed: 2023/10/4)

- Summary of container seedling production test results using cedar bark compost [seedlings of cedar, cypress, and larch] https://www.rinya.maff.go.jp/j/kanbatu/houkokusho/attach/pdf/syubyou-3.pdf (accessed: 2023/10/10)

- References

-

- National Bark Compost Industry Association, 2007, Soil improvement designated material, bark compost – vitalizing the soil, published by National Bark Compost Industry Association

- Taguchi, Kinokasumi, Tamaki, Ichiro, Mogi, Yasukazu, Possibility of growing Hinoki seedlings in containers using locally produced materials with low CO2 emissions, Journal of the Japanese Forest Society, 2023, Vol. 105, No. 7, pp. 233-238

- Other

-

From the perspective of composting forestry residues, the Japan Bark Compost Association uses the catchphrase “From trees to soil. From soil to trees” to promote bark compost as an environmentally friendly organic soil improvement material.

Since the early 2000s, there has been growing expectation for using bark compost as base soil for container seedlings used in the integrated work system of Japanese reforestation technology. Compared to imported coconut shell peat (Figure 5), which has been conventionally used as base soil for container seedlings, using bark compost as base soil is thought to contribute to a stable supply and reduction of carbon dioxide emissions during transportation through local production and consumption, promoting recycling-based forestry. Research on using bark compost as base soil for container seedlings has ascertained that seedlings using bark compost have inferior growth characteristics to those of seedlings using coconut shell peat as base soil. However, in some cases, seedlings have grown to the same level as those using coconut shell peat by mixing secondary materials such as perlite, which improves drainage, with bark compost as a remedy. Efforts are expected to progress toward the practical use of bark compost in reforestation.

Figure 5. Coconut shell peat

Your Knowledge could start making a change, when issue is faced; in forest conservation, or in value chains to use forest resources in a sustainable way.

Your Feedback.