- Knowledge Overview

-

In recent years, wood has been attracting attention as a sustainable resource with low environmental impact, and examples of 7- and 10-story wooden office buildings have been increasing in Japan’s urban areas, mainly for private demand. In October 2021, the Japanese government promulgated the “Act on the Promotion of the Use of Wood in Buildings, etc. to Contribute to the Realization of a Decarbonized Society, etc.” (commonly known as the “Act for Promoting Wooden Construction in Cities that Utilizes Forests”) and is implementing measures to promote wood use in order to increase wood demand and realize a sustainable society.

On the other hand, for mid-to-high-rise wooden buildings to be realized, fire resistance standards, the weight of the building itself, structural strength against earthquakes, typhoons, etc., and appropriate material procurement are required. Our company (Shelter Inc.) has researched and developed the KES construction method and the wooden fireproof material COOL WOOD, which is a wooden building knowledge, and when compared with steel-framed structures and reinforced concrete structures, wooden structures are attracting attention as a practical material because they improve on the deficiencies in fire resistance standards, structural strength, and processing infrastructure that have been pointed out in the past. If this knowledge spreads throughout the region, it will be possible to promote the use of wood that is at an appropriate harvesting age, revitalize local regions through local production for local consumption, and contribute to the creation of a society that is kind to people and the global environment.

Japan is also known as a disaster-prone and disaster-prevention-oriented country, and has a history of frequently suffering damage from earthquakes and tsunamis such as the Great East Japan Earthquake. Similar damage has often been reported in Southeast Asia, inland China, and South America. The use of high-performance construction methods and components is expected to serve as disaster-prevention knowledge that can protect the lives of people in these countries.

- Background (history and development)

-

Shelter Inc. was founded in 1974 in Yamagata Prefecture in the Tohoku region of Japan, and in addition to researching, designing, manufacturing, and selling uniquely developed wooden structural components, we have developed a wide range of businesses, including the design (design, structural design, calculation), and construction of wooden buildings (large-scale, medium-to-high-rise buildings, and fireproof), wooden fireproofing design, wooden fireproofing consulting, planning and coordinating the creation of timber cities.

At the time of its founding, the company expanded its business by independently developing and standardizing the “KES construction method,” a “joint hardware method for wooden buildings,” in order to strengthen joints, which were said to be the biggest weakness in wooden buildings. This “KES construction method” has dramatically improved earthquake resistance strength and design flexibility compared to the conventional timber framework method. “KES construction method” was patented in many countries around the world. Today, it is widely used in a wide range of applications, from residential housing to large-scale, medium- and high-rise wooden buildings.

In order to promote large-scale, medium- and high-rise wooden buildings, it is necessary to develop fire-resistant structural materials that meet the regulations of the Building Standards Act. For this reason, the company began research and development of wood fireproof material in 2001. Subsequently, in June 2013, it cleared the one-hour fire resistance standard and obtained certification from the Minister of Land, Infrastructure, Transport and Tourism. This was named “COOL WOOD,” a fireproof wood material. Furthermore, in December 2017, we developed pillars and beams made of the wooden fireproof material COOL WOOD, and became the first company in Japan to pass the 3-hour fire resistance standard and receive certification from the Minister of Land, Infrastructure, Transport and Tourism. The development of this has made it possible to build wooden structures without height restrictions.

In April 2021, we completed the construction of the Takaso Mokko Building (Photo 1: Takaso Mokko Building), Japan’s first 7-story building made entirely of pure wood with fireproof wood material “COOL WOOD” and an applied method of bundling lumber. The unique feature of this construction project is that it utilizes existing processing infrastructure and lumber, making it the first example in Japan of local production for local consumption, where everything from lumber procurement to construction can be completed near the construction site.

Photo 1_Takaso Mokko Building - Technology (specific knowledge methods)

-

KES construction method

It is the first metal joinery hardware construction method for wood-built structures developed and standardized in Japan. Since the completion of the prototype in 1974, repeated improvements have been made and patents have been acquired in various countries around the world. This joinery hardware was developed with the mission to “protect the precious lives of families and properties.” This construction method thoroughly strengthens the workability and strength of wooden construction by using our unique joint hardware, instead of the “mortise” and “tenon,” processing that used to rely on the carpenter’s intuition and experience. Because of its ability to create large spaces and spans, it offers a high degree of freedom in architectural design, and is now widely used in everything from residences to large-scale, medium- and high-rise public wooden buildings.

Figure 1_CG of joints The Kurikoma General Branch Office of the KES construction method was used as a Disaster Management Headquarters.

In June 2008, an earthquake of magnitude 7.2 (preliminary data from the Japan Meteorological Agency) occurred with its epicenter in the southern inland region of Iwate Prefecture. However, the Kurikoma General Branch Office in Kurikoma City, Miyagi Prefecture, located 7 km from the epicenter, remained unscathed amidst cracks in the ground and mudslides in the surrounding area. This government building was constructed using the KES construction method. This is why it was utilized as a disaster management headquarters. The existence of this government building has made people aware of the importance of earthquake-resistant structures.

Photo 2_Kurihara City General Branch Office

Photo 3_Disaster Management Headquarters High earthquake resistance that withstood the Great East Japan Earthquake and the massive tsunami

In the Great East Japan Earthquake, a tsunami of more than 15 meters, far exceeding the height of buildings, hit Minamisanriku-cho, Miyagi Prefecture. With no buildings remaining in the surrounding area, only the Utatsu Community Center, which used the KES construction method, remained. The structure of the community center showed no signs of tilt or deformation. (Minamisanriku-cho, Miyagi, total floor space 1,010m2, 2 floors above ground)

Photo 4_ Before the earthquake

Photo 5_After the earthquake COOL WOOD, Fireproof wood material

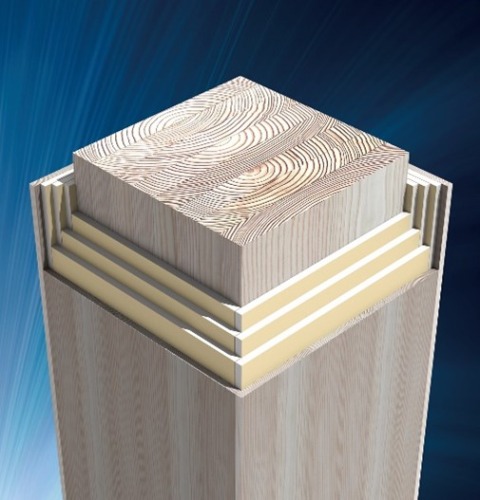

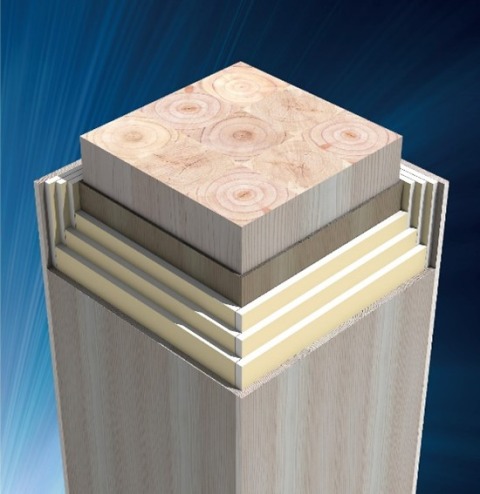

COOL WOOD, a wood fireproofing material, is a product in which a core piece of wood is surrounded by a gypsum board, and the outside is further covered with wood. In addition to being low cost and easy to process, the wood species can be selected to suit the design and cost. The exterior of the pillars and beams is made of wood, making it possible to create a building that takes advantage of the warmth of wood. In addition, there is an established method for using bundled lumber, which is a commonly distributed material, and it also has the economic advantage of being able to complete traceability from wood procurement to processing, local manufacturing, and construction near the construction site.

COOL WOOD is constantly supplied from cooperating factories across Japan, and the technology is open through the Japan Fire-proof Timber building Association https://mokutaiken.or.jp/ , where know-how and information are actively provided.

Figure 2_COOL WOOD_1-hour fireproof specification

Figure 3_COOL WOOD_2-hour fireproof specification

Figure 4_COOL WOOD_3-hour fireproof specification - Examples of Applying Knowledge

-

Example of how lumber is used in the “Takaso Mokko Building,” Japan’s first pure wooden 7-story building

The “Takaso Mokko Building” was constructed in front of the east exit of Sendai Station. This was the first pure wooden seven-story building in Japan. The load-bearing parts of the “COOL WOOD,” wood fireproofing materials used are from 100% JAS lumber, which is a commonly distributed material, and also structural components such as pillars and beams were procured from the area surrounding the construction site (mainly Iwate, Miyagi, and Fukushima, but also Aomori and Tochigi). Procuring materials from surrounding areas also has the advantage of reducing CO2 emissions because the transportation distance for parts production is shortened.

Photo 6_Exterior view of the Takaso Mokko Building

Photo 7_Interior view of the Takaso Mokko Building Large section made of lumber

At the Takaso Mokko Building, structural timbers are made by joining products with small cross sections together using shear plates (split rings). In most cases, glue is used to produce laminated wood, but this wooden building uses “composite compression materials (bundling pillars)” to increase the cross section by bundling the laminated wood without using glue. The beams are also made in the same way, using “gassho-type laminated beams,” which are made of laminated lumber that is generally distributed in the market, and have a large cross section by matching them together. The total volume of cedar and Japanese cypress lumber used for the foundation, braces, pillars, and beams of this building was 454m3, which is equivalent to fixing 269 tons of CO2.

Figure 5_COOL WOOD bundling pillars 2-hour fireproof specification CG

Photo 8_COOL WOOD production scene 1 of bundling pillars

Photo 9_COOL WOOD production scene 2 of bundling pillars

Photo 10_COOL WOOD bundling pillars of 2-hour fireproof specification About Timber Distribution

The background of our company’s efforts to develop wood fire-resistant structures and composite compression materials (bundling pillars) using lumber was our desire to expand the market for medium- and large-scale wooden buildings by addressing the issues faced by lumber distribution in Japan.

In Japan, mature artificial forests that can be harvested are widely distributed, but the distribution of JAS (Japan Agricultural Standards) certified factories that can manufacture structural materials used in buildings is limited. In the pre-cut process, where logs are processed to make structural timbers, special large-scale processing machines must be used for laminated timbers. For this reason, even if we consider manufacturing CLT or laminated timber using locally produced logs, the reality is that the materials are often transported long distances from the production area to the manufacturing plant and construction site.

On the other hand, there are numerous general sawmills throughout the country, and the production infrastructure is well established. Bundling pillars are a technique of combining small cross sections of lumber from sawmills to make larger cross sections. Wood with a small cross section is easy to process, so it can be processed using conventional hand-held processing machines. Another feature is that each component is small and light, and it has the advantage that pre-cut production can be performed using processing machines commonly owned by carpenters and construction companies. Also, compared to laminated wood, it takes less time from manufacture to delivery.

Summary

This Takaso Mokko building is located in a commercial district and must be fire-resistant. A 7-story wood-frame building is required by law to have a 2-hour fire-resistance standard. “COOL WOOD” (columns and beams; 1- and 2-hour fireproof specification, floors; 2-hour fireproof specification) meets these standards. Wooden building construction using ordinary lumber can use the infrastructure around the construction site, which is close to the forests where the materials are produced, and has a higher economic impact of returning funds upstream in the supply chain. It can also contribute to the development of the forestry industry by supporting local production for local consumption and regional development. The scale of the seven-story building is large enough to accommodate the market, which accounts for more than 90% of the buildings constructed in Japan each year. This project has become a good model case in terms of increasing demand for wood and reducing environmental impact as we aim to create a sustainable society.

When this technology is used overseas, it is expected to have many advantages, such as reducing the cost of wood procurement and the economic burden of transportation, since local wood can be procured and processed and installed with existing infrastructure without using large processing machines.

Furthermore, damage similar to the earthquake and tsunami caused by the Great East Japan Earthquake has often been reported in Southeast Asia, inland China, and South America. We believe that high-performance construction methods and components can contribute to these communities as disaster prevention technology that also brings safety and security.

- Positioning and Characteristics of Knowledge in Japan

-

COOL WOOD’s patents are open to technology through the Japan Fire-proof Timber building Association (membership: over 500 industry, academic, government, and private organizations). As a member, you can attend manual training sessions organized by the association and use the technology. The manual is supervised by the Building Research Institute and in addition to the 1-, 2-, and 3-hour fireproof materials approved by the Minister, it contains a total of 30 types of minister-certified content provided by members and managed and operated by the association. The technology is closed to non-members to ensure that rights are protected and properly operated. The association regularly holds events to introduce actual examples of wood use expansion, and provides information to engineers who want to build with wood.

- Owners/inheritors of knowledge

-

Shelter Inc. https://shelter.inc/

Contact https://shelter.inc/contact/form-case

Shelter Inc.

〒108-0014

Shiba Mita Mori Building 3F, 13-15 Shiba 5, Minato-ku, Tokyo

Tel: 03-5418-8800, Fax: 03-5418-8801 - Related URLs (in Japanese)

-

- Shelter Inc. https://shelter.inc/

- About KES Construction Method https://shelter.inc/technical/kes

- About COOL WOOD https://shelter.inc/technical/coolwood

- Other

-

- (General Incorporated Association) Japan Fire-proof Timber building Association https://mokutaiken.or.jp/

- About Manual Training Sessions https://mokutaiken.or.jp/news_detail/20220901/

Your Knowledge could start making a change, when issue is faced; in forest conservation, or in value chains to use forest resources in a sustainable way.

Your Feedback.