- Knowledge Overview

-

TROMSO Co., Ltd.’s rice husk briquette making machine (Grind Mill) uses unused rice husks to produce a stick-shaped briquette fuel called “momigalite.” Because rice husks are rich in silica (silicic acid; about 20%), parts of conventional saw dust forming machines can easily wear out and become unusable. Based on the technology cultivated in Japan’s shipbuilding industry, TROMSO has developed a machine that uses special metal on the surface of parts to increase durability and is resistant to wear even when using rice husks. Momigalite can be used in the daily lives of people in developing countries in homes, commercial restaurants, schools, etc., and can also be used as an alternative to fossil fuels in times of disaster. It can also be used as fuel for industrial boilers to help reduce carbon dioxide emissions at business sites. Momigalite can be used in place of firewood or charcoal. In developing countries where wood charcoal is exclusively used for boiling and cooking, this could lead to forest conservation. It can be molded by mixing with woody organic materials such as saw dust, and is expected to lead to effective use of unused biomass resources from the forests.

- Background (history and development)

-

About 2.1 million tons of rice husks are generated annually in Japan. About 800,000 tons of this is unused and disposed of as industrial waste. TROMSO developed the “Grind Mill” with the goal of utilizing unused rice husks. TROMSO is based on Innoshima Island (Onomichi, Hiroshima Prefecture), where the main industry used to be shipbuilding, which was at its peak in the 1970s. TROMSO’s parent company was also a manufacturer and seller of heat exchangers for ships. Due to the decline of the shipbuilding industry on Innoshima and the founder’s idea, the company spun out a new business that uses the heat exchanger technology.

- How to Apply Knowledge

-

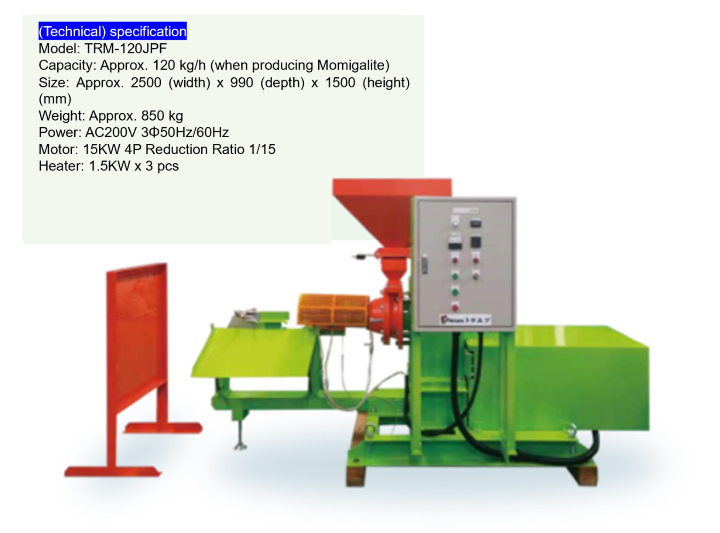

A “Grind Mill” is a device that grinds woody residues such as rice husks and saw dust, and then solidifies them through a compression and heating process. Each device can convert 120 kg of raw materials into solid fuel per hour, and the yield is almost 100%. Through the compression molding process, the volume of the solid fuel is greatly reduced, becoming approximately one-tenth the volume of the solid fuel compared to rice husk. No adhesives or other materials are added, and almost no toxic gases (NOx, SOx, etc.) are generated during combustion. The calorie content of stick-shapes briquettes (solid fuel) is approximately 4,000 kcal/kg, which is equivalent to firewood. Since materials such as rice husks are plant-based, they emit zero new carbon dioxide, making them a carbon-neutral fuel.

Rice husks contain a lot of silica, which causes the metal parts to wear out quickly, but Grind Mill use special surface finish on the main parts, which greatly improves their wear resistance. This special processing technology of TROMSO maintains an advantage over competitors.

In this Knowledge Project, unused woody organic materials such as saw dust will be mixed with rice husks in Cambodia to make the material, which will be used to produce solid fuel in a Grind Mill. Woody organic matter has a slightly higher moisture content than rice husk, but by adjusting the moisture content to around 15% and mixing the woody organic matter within 50%, briquettes could be formed.

Picture: Grind Mill (Rice husk solid fuel production equipment/rice husk manual feed type)

Picture: Finished look of Momigalite (rice husk solid fuel) - Examples of Applying Knowledge

-

In Japan, Grind Mill have been installed in rice mills of agricultural corporations and construction-related businesses to utilize rice husks generated on their premises or nearby and convert them into fuel and agricultural materials. The materials produced will be used as an alternative to fossil fuels for in-house heating equipment and as soil for growing seedlings. In addition, there are many examples of applying knowledge where products are sold and developed as businesses.

An example of a precedent activity overseas is the 2013-2014 JICA Small and Medium Enterprise Business Project, “Verification Survey with the Private Sector for Disseminating Japanese Technologies for Utilization of Resources through Rice Husk Briquette Machines” in Tanzania. From 2014 to 2017, they also worked on the JICA Small and Medium Enterprise Business Project of “Verification Survey with the Private Sector for Disseminating Japanese Technologies for Utilization of Resources through Rice Husk Briquette Machines” in Tanzania. In Tanzania, a study was conducted that included the contribution of momigalite to solving various problems caused by changes in forest area and deforestation. In Tanzania, deforestation is progressing due to increased use of firewood and charcoal, while rice production and consumption is expanding, so if one Grind Mill (this knowledge) is introduced, 180 tons of solid fuel can be produced annually. It was estimated that if the same amount of solid fuel could be produced and replaced with charcoal, it would have the effect of conserving 22.5 hectares of forest. In addition, if a solid fuel production business using this momigalite is established, it is expected to create new industries and employment.

- Positioning and Characteristics of Knowledge in Japan

-

As the shortage of farmers accelerates, more and more younger generations are establishing agricultural corporations and undertaking intensive rice cultivation from elderly farmers. If the cultivated area increases due to the intensification of rice cultivation, the amount of rice husk generated will increase proportionately. Since open burning of rice husks is now prohibited, rice husk disposal has become a major problem. Some agricultural corporations are paying more than 1 million yen per year to industrial waste companies for rice husk disposal. By installing TROMSO Grind Mill, rice husks that were previously treated as waste can be used as a resource and converted into solid fuel or ground rice husks (agricultural materials). Using the Grind Mill adds value to rice husks with business potential, instead of having no choice but to discard them.

In recent years, social interest in “climate change and the environment” has increased, and companies that regularly use fossil fuels such as coal-fired power generation have come under increasing criticism. Mixed combustion of coal and biomass and biomass-only combustion are attracting attention, and Momigalite is attracting attention as a “carbon-neutral” fuel that does not emit new CO2. Inquiries for solid fuels made from rice husks and other materials are increasing from major trading companies.

- Owners/inheritors of knowledge

-

TROMSO Co., Ltd.

CEO: Masaaki Uesugi

E-mail: m-uesugi@tromso.co.jp - Related URLs (in Japanese)

-

- https://tromso.co.jp/ (TROMSO Co., Ltd. Website)

- http://www.unido.or.jp/en/technology_db/2673/ (UNIDO STePP introduction page)

Your Knowledge could start making a change, when issue is faced; in forest conservation, or in value chains to use forest resources in a sustainable way.

Your Feedback.